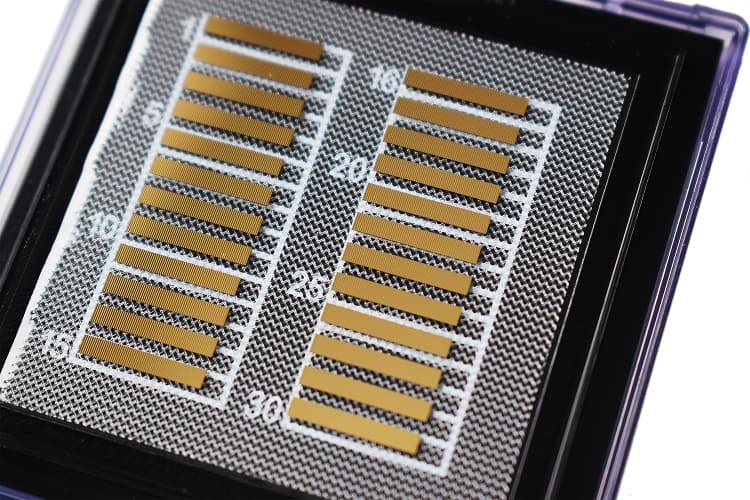

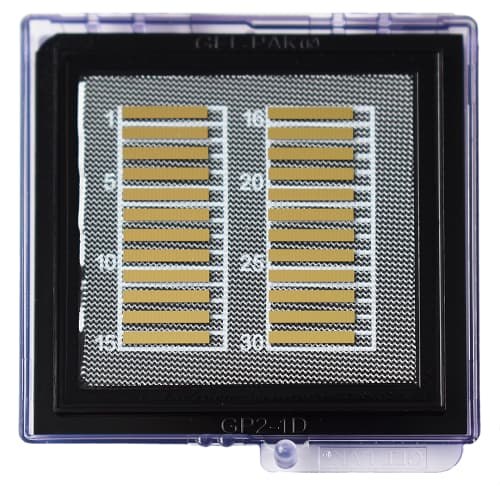

Laser bars and chips

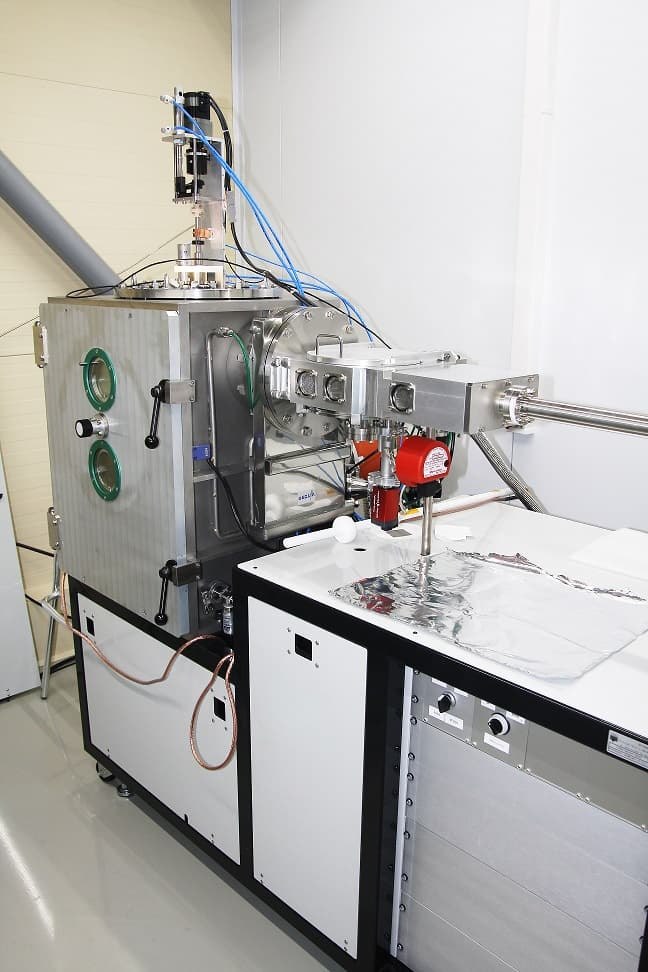

MOCVD, a vapor-phase epitaxy, is based on delivery of initial components of epitaxial layers in form of highly volatile elementary substances or compounds via a carrier gas flow into a growth zone. These materials induced thermally or else decompose in the reactor and interact chemically, while desired components deposit on a substrate which serves as a basis of a semiconductor device.

ASTRUM LT offers CONTRACT R&D:

CUSTOM MOCVD EPITAXY

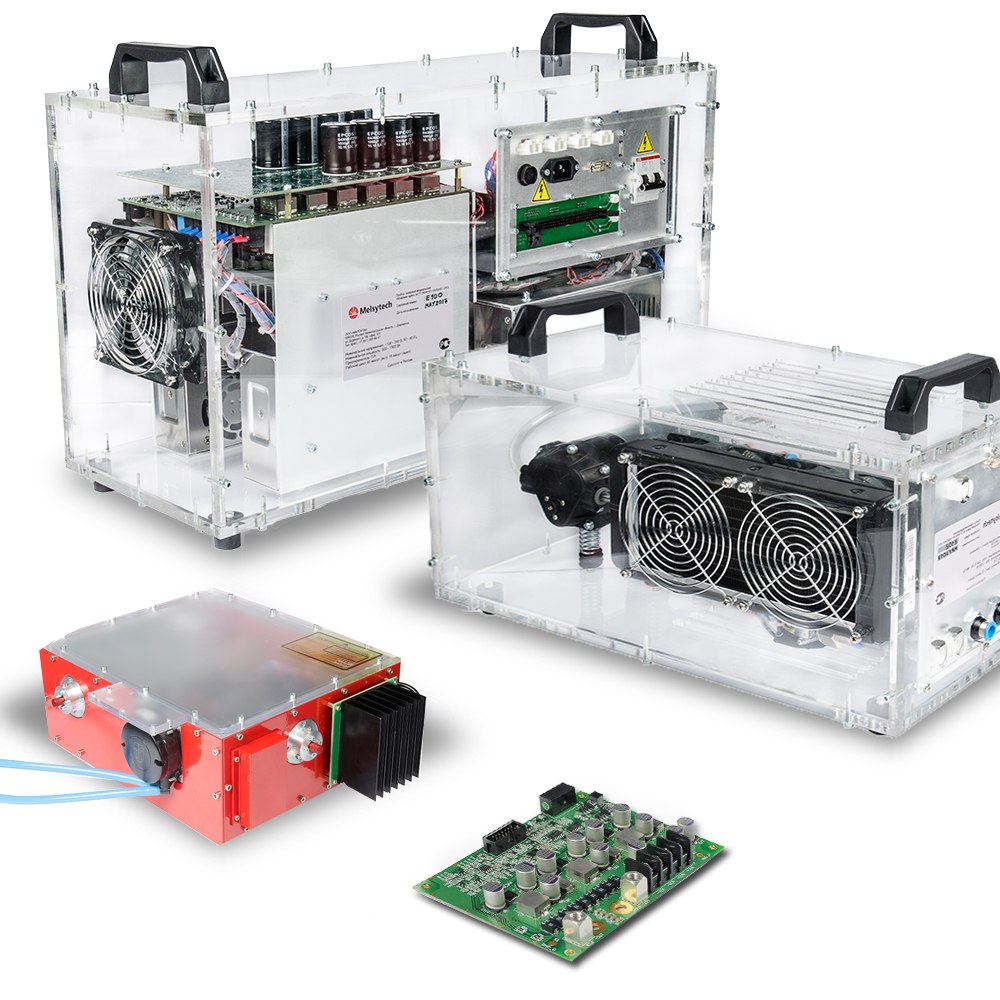

CUSTOM LASER DIODE BARS

Custom wavelength

CW or QCW, up to 200W

-

MOCVD technology offers a number of advantages:

- Exceptionally high quality of layers: higher growth rate at high doping uniformity and consistency.

- High yield: no need for ultra-high vacuum allows for better up-time.

- Flexibility: growth of various materials and during the same process run.

- Growth of multi quantum wells structures (MQW structures).

CUSTOM LASER DIODE BARS

Custom wavelength

CW or QCW, up to 200WMOCVD CAPABILITIES

AlGaInP/GaAs LED, lasers 635 – 780nm automotive industry, street lights, DVD, displays

AlGaAs/GaAs lasers 780 – 1060nm CD, telecommunication, high power lasers

AlInAs/GaInAs/InP LED, lasers 1300 – 1600nm IR - diodes, high power optical modulesMOCVD CAPACITIES

AIXTRON with configurations of 2", 3", or 4” wafers

Doping concentration from 1E13cm-3 to 1E20cm-3IN-HOUSE MOCVD CHARACTERIZATION

Surface defects mapping

X-ray diffraction

ECV profiling

Wafer photoluminescence (PL) mapping

Scanning Electron Microscopy (SEM)